How to build a rope tow.

12

Jan 15, 2018; 4:44pm

Jan 15, 2018; 4:44pm

Jan 16, 2018; 1:01am

Jan 16, 2018; 1:01am

Jan 16, 2018; 1:03am

Jan 16, 2018; 1:03am

Jan 16, 2018; 2:52am

Jan 16, 2018; 2:52am

Jan 19, 2018; 7:15pm

Jan 19, 2018; 7:15pm

Jan 19, 2018; 9:30pm

Jan 19, 2018; 9:30pm

Jan 19, 2018; 10:37pm

Jan 19, 2018; 10:37pm

Jan 19, 2018; 10:45pm

Jan 19, 2018; 10:45pm

Jan 19, 2018; 10:54pm

Jan 19, 2018; 10:54pm

Jan 21, 2018; 5:05pm

Jan 21, 2018; 5:05pm

Jan 22, 2018; 2:19am

Jan 22, 2018; 2:19am

12

Reply |

Threaded

Open this post in threaded view

|

More ♦

♦

| Loading... |

| Reply to author |

| Edit post |

| Move post |

| Delete this post |

| Delete this post and replies |

| Change post date |

| Print post |

| Permalink |

| Raw mail |

|

Re: How to build a rope tow.

Yeah the stop gate is key with or without the grippers. I took those pics when we visited Mount Greylock ski club last year. They have a bunch of those there, original equipment from the 30s. I was concerned about them not letting go but it turned out not to be a factor. I also took a couple rides without using the gripper and I can tell you, they make a HUGE difference. Of course that tow is probably a lot longer and faster then what Ethan put together.

"You want your skis? Go get 'em!" -W. Miller

|

Reply |

Threaded

Open this post in threaded view

|

More ♦

♦

| Loading... |

| Reply to author |

| Edit post |

| Move post |

| Delete this post |

| Delete this post and replies |

| Change post date |

| Print post |

| Permalink |

| Raw mail |

|

Re: How to build a rope tow.

|

In reply to this post by Harvey

That thing doesn't keep tension at all. All that does is increase the surface area of the bull wheel gripping the rope, and it does that job well. It was actually an afterthought, and it's a bit cob job, but there's room for improvement there. The tensioner is at the bottom of the hill and uses gravity to keep tension. I know I have better pictures somewhere, but I found this.  There's a hinged arm on there which is pulled tight by the concrete blocks that hang off the cable.

I'll take boilerplate ice over wet snow any day

|

Reply |

Threaded

Open this post in threaded view

|

More ♦

♦

| Loading... |

| Reply to author |

| Edit post |

| Move post |

| Delete this post |

| Delete this post and replies |

| Change post date |

| Print post |

| Permalink |

| Raw mail |

|

Re: How to build a rope tow.

|

In reply to this post by Marcski

That's up to Harv. You can always email me if you want to do a day trip from your place in Roxbury.

I'll take boilerplate ice over wet snow any day

|

Reply |

Threaded

Open this post in threaded view

|

More ♦

♦

| Loading... |

| Reply to author |

| Edit post |

| Move post |

| Delete this post |

| Delete this post and replies |

| Change post date |

| Print post |

| Permalink |

| Raw mail |

|

Re: How to build a rope tow.

|

In reply to this post by tBatt

I'm not 100% sure what the maximum load is. The specs on that gear box I believe are rated somewhere in the ballpark of 450 Ft.lbs. But it really depends on how much power you put into it from the engine. The wheel/tire is 22" so that means that the rope is placed 11" from the axle which is close to one foot. So theoretically it can pull a little over 450 lbs. Now keep in mind, you can have a lot more than 450 lbs on the line because it isn't holding the entire weight of the riders, it's simply sliding them across the ground (uphill). My previous system ran on a small Briggs and Stratton engine and a hydrostatic drive that maxed out at 170 ft. lbs. As it approached max load it would slow down, and once it hit max It would nearly come to a stop. This kept the engine from stalling out. It was good for about 2 adults or 3 kids. The electric start Honda was a huge upgrade while doubling the HP. I believe the weakest link at this point would be the rope itself. As I said before, it's due for a replacement, but it's not urgent. That will happen next season. As long as the tensioning system is working properly, the grip between the rope and tire is pretty solid.

I'll take boilerplate ice over wet snow any day

|

Reply |

Threaded

Open this post in threaded view

|

More ♦

♦

| Loading... |

| Reply to author |

| Edit post |

| Move post |

| Delete this post |

| Delete this post and replies |

| Change post date |

| Print post |

| Permalink |

| Raw mail |

|

Re: How to build a rope tow.

|

I'll take boilerplate ice over wet snow any day

|

Reply |

Threaded

Open this post in threaded view

|

More ♦

♦

| Loading... |

| Reply to author |

| Edit post |

| Move post |

| Delete this post |

| Delete this post and replies |

| Change post date |

| Print post |

| Permalink |

| Raw mail |

|

Re: How to build a rope tow.

|

In reply to this post by Ethan Snow

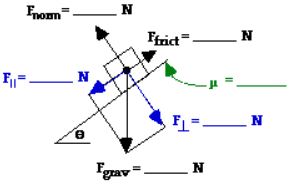

µmgcosΘ+mgsinΘ, per skier, where µ is the coeffecient of friction between skis and snow, mg is the weight of the skier, and Θ is the slope angle.

That would mean it requires roughly 60 lbs of force to haul a 175 skier up a 18° slope (blue square), not including mechanical losses from the system itself.  I should probably finish my engineering degree  Funny, Miker and I had this conversation ca. 2009 when we were talking about building a portable rope tow on the hill behind our neighborhood. I didn't think it was possible to do tension issues and grip from the rope diameter. Looks like you've ended a long time debate that he knew he had already won. |

Reply |

Threaded

Open this post in threaded view

|

More ♦

♦

| Loading... |

| Reply to author |

| Edit post |

| Move post |

| Delete this post |

| Delete this post and replies |

| Change post date |

| Print post |

| Permalink |

| Raw mail |

|

Re: How to build a rope tow.

|

In reply to this post by Ethan Snow

That is a cool video- looks like you're getting pretty good speed out of it

"You want your skis? Go get 'em!" -W. Miller

|

Reply |

Threaded

Open this post in threaded view

|

More ♦

♦

| Loading... |

| Reply to author |

| Edit post |

| Move post |

| Delete this post |

| Delete this post and replies |

| Change post date |

| Print post |

| Permalink |

| Raw mail |

|

Re: How to build a rope tow.

|

This post was updated on Jan 19, 2018; 11:07pm.

Haha, the video is 3X speed. No way you could grab on to it going that fast and not get your arm ripped off, or your gloves worn through trying to grab on. The rope is 750' long one way, and it takes almost exactly 1:30 to ride up, unless I run it slow for beginners. That's 500 Ft/min which is the speed of most fixed grip chairlifts. If the lift were actually going that fast, it would be 1500 ft/min which is faster than any detachable lift in, I think, the world. 1,200 ft/min is a really fast gondola. The Skyeship at Killington sometimes runs that fast.

I'll take boilerplate ice over wet snow any day

|

Reply |

Threaded

Open this post in threaded view

|

More ♦

♦

| Loading... |

| Reply to author |

| Edit post |

| Move post |

| Delete this post |

| Delete this post and replies |

| Change post date |

| Print post |

| Permalink |

| Raw mail |

|

Re: How to build a rope tow.

|

In reply to this post by tBatt

I had to take physics in college last year. I remember doing problems like this. I'm less of an engineer, and more of a mechanic. I just take knowledge from real life experiences, and say, ok, well if I do this, this, and this, and use this, this, and this, it should work. Most of the time it does. If I were a physicist, I probably wouldn't have a clue where to start when it comes to building stuff. Keeping tension on the returning rope is key. If you have a mechanism that holds the returning rope tight, you will have no traction issues. as soon as that return rope gets lose, you're screwed.

I'll take boilerplate ice over wet snow any day

|

Reply |

Threaded

Open this post in threaded view

|

More ♦

♦

| Loading... |

| Reply to author |

| Edit post |

| Move post |

| Delete this post |

| Delete this post and replies |

| Change post date |

| Print post |

| Permalink |

| Raw mail |

|

Re: How to build a rope tow.

Seems like many of them don't. Having the ability to practically conceptualize the project is where it all begins and what many engineers out there lack. Design it, figure out the forces acting on it, build accordingly. A good buddy of mine wasn't a star student, he had to take most of his classes twice before getting a passing grade. I crashed at his house one night and he had all sorts of projects he was fiddling with in his free time - building his own stereo amplifier, building a turbocharger that used an electric motor to prespool so there was no turbo lag, etc. He graduated with a mechanical engineering degree, got a job with Toyota TRD, and was part of a small crew that designed their race car for nascar. With the skills you have, you'll be alright. |

Reply |

Threaded

Open this post in threaded view

|

More ♦

♦

| Loading... |

| Reply to author |

| Edit post |

| Move post |

| Delete this post |

| Delete this post and replies |

| Change post date |

| Print post |

| Permalink |

| Raw mail |

|

Re: How to build a rope tow.

|

I'm Currently going to school for Mechatronics. Sounds like your buddy probably would have done well with this degree. Thankfully the highest math you have to take is Pre-calc, and the highest science is Algebra-based physics. I had to take Pre-Calc twice. Passed Physics just fine, but it was the most difficult course I've taken. All the other courses are very hands-on.

A lot of what we do is Electrical Process control work, but also a lot of other cool mechanical type stuff like SolidWorks, Welding, machining, hydraulics, and Pneumatics. You can put this degree to work anywhere. Maybe even in the ski industry. http://www.delhi.edu/academics/majors-programs/bachelors/mechatronics/ I'm not gonna lie, it's a super laid back campus. The lab facilities are awesome, and the faculty are super friendly too. I made several of the new parts for the rope tow this year in the Welding lab there.

I'll take boilerplate ice over wet snow any day

|

«

Return to Woodstove Archive

|

1 view|%1 views